tREXS

- A single grating in the jig that is used to attach the ribs to the back-side of the grating surface. These ribs ensure that the gratings have the correct spacing, roll, and pitch when assembled into the stack.

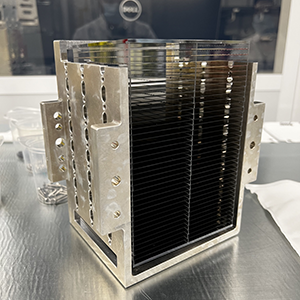

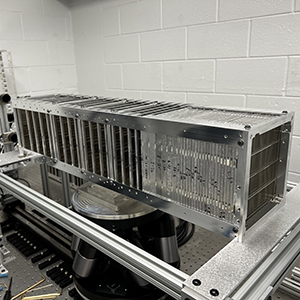

- A single grating stack ready to be mounted to the optical bulkhead (38 co-aligned gratings)

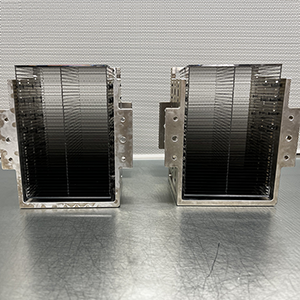

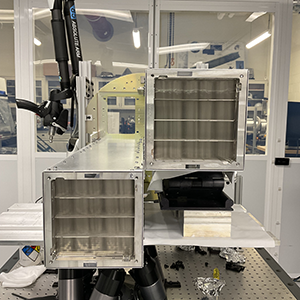

- Two complete grating stacks in their modules ready to be mounted onto the optical bulkhead behind their respective mechanical beam sculptors

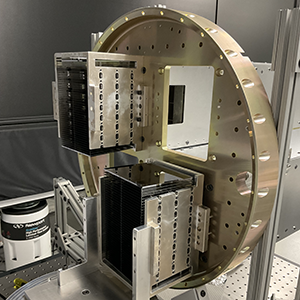

- The grating modules mounted onto the optical bulkhead ready to be installed into the instrument

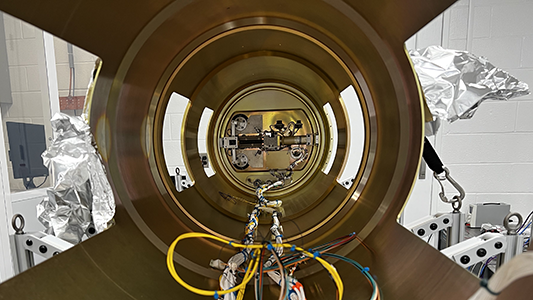

- The inside of one of the mechanical beam sculptors. Wire plates sculpt the incoming X-ray beam into a line-spread profile with each plate containing the same number of blocking wires, but at closer spacing. This ensures that only X-rays that will naturally focus on the focal plane are able to make it through sculptor.

- Front on view of the mechanical beam sculptors that make up the 2 channels of the tREXS telescope..

- A side view of the 2 mechanical beam sculptors. In the bottom right, the mount for the star-tracker can be seen.

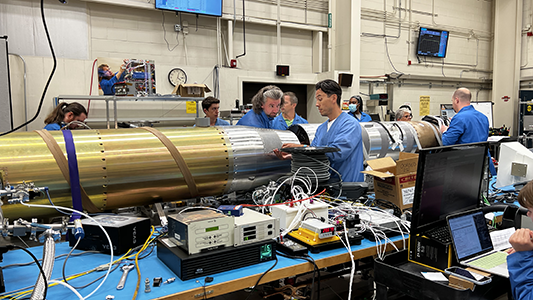

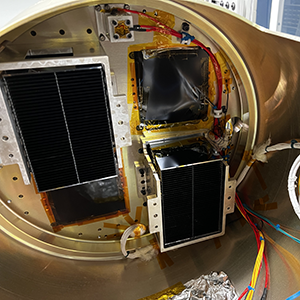

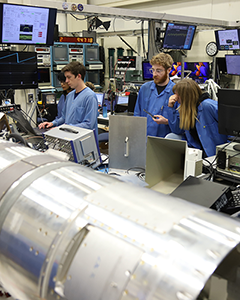

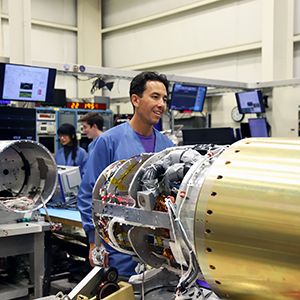

The inside of the tREXS optical bench. At the far end of the tube is the detector shutter door, protecting the cold camera from the telescope tube environment. Harnessing runs along the bottom of the optical bench to control the external shutter door and star-tracker. Then holes in the side of the optical bench allow access for harnessing before the optical bench slides into the external skins.

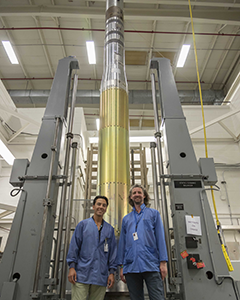

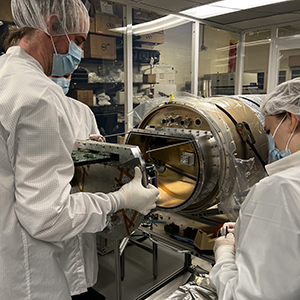

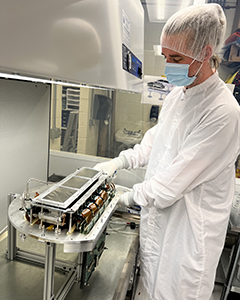

Dr. James Tutt assembling the tREXS focal plane camera in the lab cleanroom.

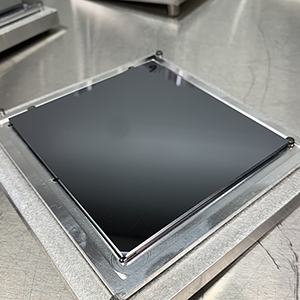

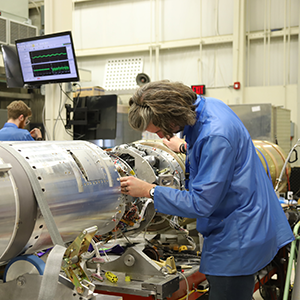

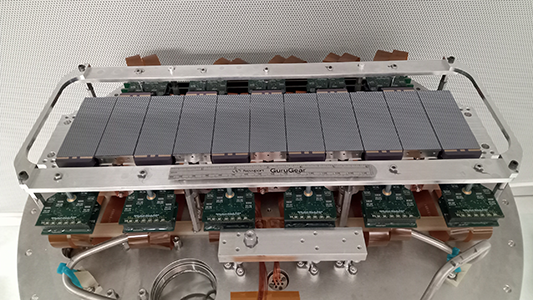

The assembled tREXS focal plane camera. The camera consists of 11 e2v CIS113 – Vega sensor tiled into a 300 x 75 mm camera. The readout electronics were also developed at Penn State University.